Lessons Learned in Expedient Improvised Protective Works

The challenges of developing effective and expedient protective works for the detonation of UXO faced by the EX-PAT EOD contractor technician in situations where safe separation distances from critical infrastructure are not an option can be met using methods more expeditious than those tended to with simply applying an adequate amount of dirt.

Dirt, soil, sand, while extremely effective in dampening the effects of a detonation and almost always available; require time and manpower resources to transport and place. Situations that today's EX-PAT EOD contractor may find themselves immersed in can require employing tactical as well as technical considerations focused toward minimizing time on scene. Developing alternatives to minimize the time required to construct hasty yet effective expedient protective works in these situations would seem to be of a paramount consideration. Concerning the development of alternatives to sandbags alone protective works constructions I have experimented with automotive tires as one such alternative.

In no way do I imply that I am an innovator by breaking new horizons through employing tires in a protective works construction. Automotive tires were, more than likely, used previously for this purpose was my initial thought. With this in mind; prior to attempting to incorporate tires into protective works training scenarios; the collective knowledge held by members of the Fragweb Forum was tapped for any previous experiences members had that they were willing to share concerning incorporating tires into a protective works application.

Several responses posted directly on the forum and several separate emails I received in response to my inquiry led me to believe that tires could (with limited effectiveness and in combination with sandbags) prove an effective commodity if employed in protective works for disposal in situ of small UXO items. To confirm the accuracy of the information I had received would require some range time.

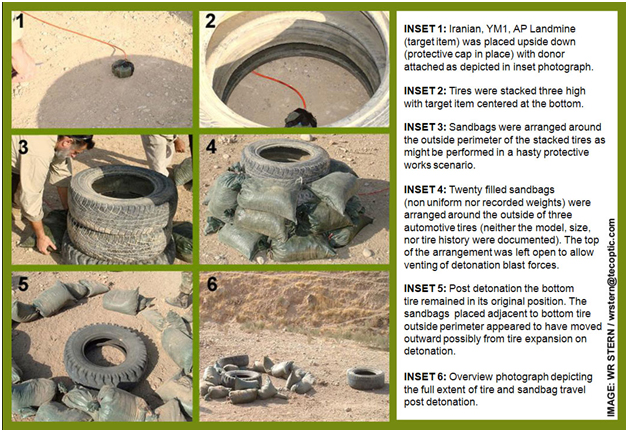

At the demolition range the target item used was an Iranian YM1 anti-personnel landmine. The antipersonnel mine offered the aforementioned desirable characteristics of a "small UXO." It contained roughly two ounces of RDX explosive and was not designed to have high fragmentation output on detonation. My intent was focused on either finding a baseline from which to move forward with experimentation of sandbag and tire protective works configurations, or to determine that the tires were unsuitable for further consideration due to some as yet unforeseen variable.

Tires and sandbags were assembled in a construction surrounding the selected target item. The mine had its protective cap still in place, so I felt confident that it could be set inverted on the ground to allow a configuration promoting optimum explosive continuity with the placed donor charge. An approximately two ounce piece of PE3 was used as donor. All other procedures used to prepare and fire the shot were performed in accordance with accepted US demolition procedures publications.

Due to information I acquired from the responses to my inquiry on the Fragweb Forum a decision was made to forego placing any covering over the top center opening formed by the stacking of the tires. This upward "chimney" was left unobstructed to allow the effects of blast to vent uninhibited. Responding comments I had received from my post indicated that any attempts by others in the past to cover the top opening of previous tire stacks built, only served to launch whatever was used as the covering.

I personally believe that with a sufficient donor charge placed appropriately over the top of a target item, the potential for upward travel of fragments is minimized due to downward forces exerted by the donor charge, thus removing the need for a top covering fragment barrier.

On examining the protective works training shot site post firing, of particular interest to me was the arrangement of the sandbags. It appeared that the bottom tire in the stack of three had expanded dramatically from blast pressures and had pushed the sandbags that had been placed adjacent to the outside tire surface outward in a circumference depicting the maximum amount the tire had stretched due to the influences of energies released on detonation of the energetic materials that were contained within (see photo, INSET 5).

Sans any high-speed camera action to catch the exact sequence of events that had transpired on detonation; any explanation for the arrangement of the sandbags on post detonation inspection was of course speculation on my part. If this speculation was correct though, the location of the sandbags on inspection of the shot area left a sobering visual displaying the immense energy released from such a small quantity of explosives.

Some considerations I had for further exploring tires as a protective works media included:

1. Purchase new tires to establish a baseline of usage.2. Number the tires for tracking identification and also as to position in stack.

3. A database could be built to track and determine which types of tires (steel belted vs. bias ply types used on the front wheels of tractors) could be used and which presented more desirable traits.

4. Maintain a log as to number of times a tire could be used before critical structural failure occurs.

5. Explore optimum patterns for vent holes cut in tires with a cutting type drill bit.

From this evolution, I observed that there could be a valid use for tires in a hasty protective works application if employed properly. In addition to that observation I also noted several questions had arisen: What are the optimum specific tire makes and models to be used with specific sandbag quantities? The steel belts in most common radial tires are possibly compromised after only one use in a protective works application. Would a tire used twice have lost its ability to maintain integrity? I considered if vent holes bored through a tire, or tire sidewall, in a yet undetermined pattern might help with the venting of detonation blast pressures or would boring holes through the tires simply weaken the tires useful properties and compromise its ability to maintain configuration on experiencing a detonation?

Most certainly if tires were placed in the technician's protective works tool box, the tires should be numbered with an identification number and tracked as to amount of exposure and position in stack during usage and removed from service at a predetermined time when it could be assumed it had reached its functional limit. This should be accomplished in an effort to preclude the unintentional addition of secondary fragmentation to any Blow In Place (BIP) procedure where tires were employed as part of a protective works configuration.

Article by Ward R Stern.